Quality

Quality :-

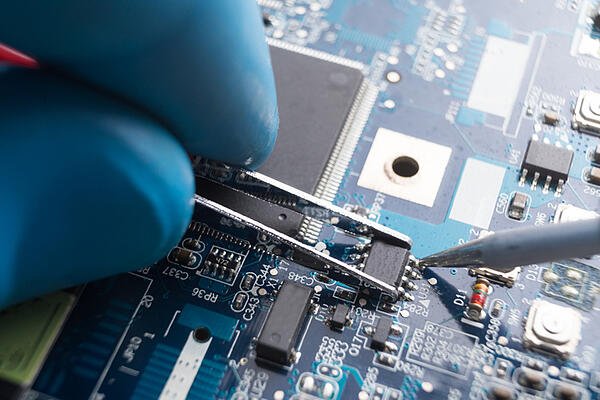

Quality is the forefront of the electronic component distribution at universal components.The biggest risk involved is the counterfeiting of components that is being traded in the open market. We provide 100 % quality assurance to our clients by applying these methods in the process of component distribution

- Package Examination

- Manufacturer P/N, logo, quantity, date code verification, RoHS

- Body marking & Physical condition Inspection

- Marking permanency tests

We provide relevant test reports to our clients prior to each delivery made to them which is our commitment.

Additional Tests :

- Decapsulation & Solderability test

- Electrical function

- X ray

Vendor Qualification :

We take great measures to ensure the success of each transaction from initial offer to final delivery. As a result, our customers receive the quality products they expect – without any surprises.

Vendor Screening :

- Formal Selection Process

- Vendor Application

- Vendor Performance aspects

Ongoing Vendor Management :

- Performance

- Credit Worthiness

- Delivery track Record

Internal Vendor Rating System Based on :

Counterfeit Detection :

- Decapsulation Machine

- X-Ray Machine

- Stereo & Metallurgical Microscopes

- XRF Analyzer

- Marking Permanency Test / Resistance to Solvents Test

- Scanning Acoustic Microscope

- Solderability Test Machine

- Counterfeit IC Detector

- General Analyzer

- Visual Inspection

- Functionality Tests

As part of our quality control process, we adhere to strict international quality standards and are actively affiliated with organizations dedicated to improving supply chain quality and security. This ensures that our internal quality processes and zero-tolerance inspection checks always exceed industry best practices.